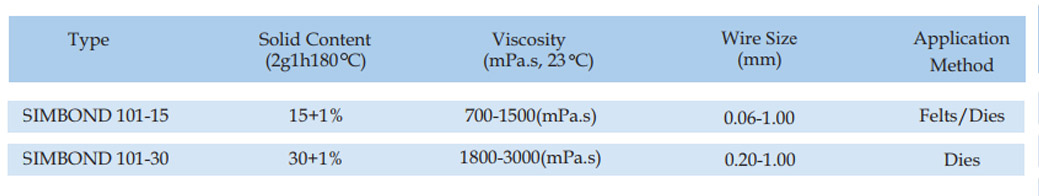

SIMBOND 101 is an aliphatic polyamide; it is very good humidity resistant. It is used in bonding layer of polyurethane as well as polyester or polyesterimide enameled wires. It can be used to produce polyurethane self bonding wire by single oven, if polyester or polyurethane self bonding wire is to be produced, we recommend dual oven machine for this purpose, the bonding coating oven should be 150 C - 250 C lower than the base coating oven. The produce can bond at temperature 140 C - 170 C. It has good bonding strength and its re-softening temperature is around 130 C - 140 C

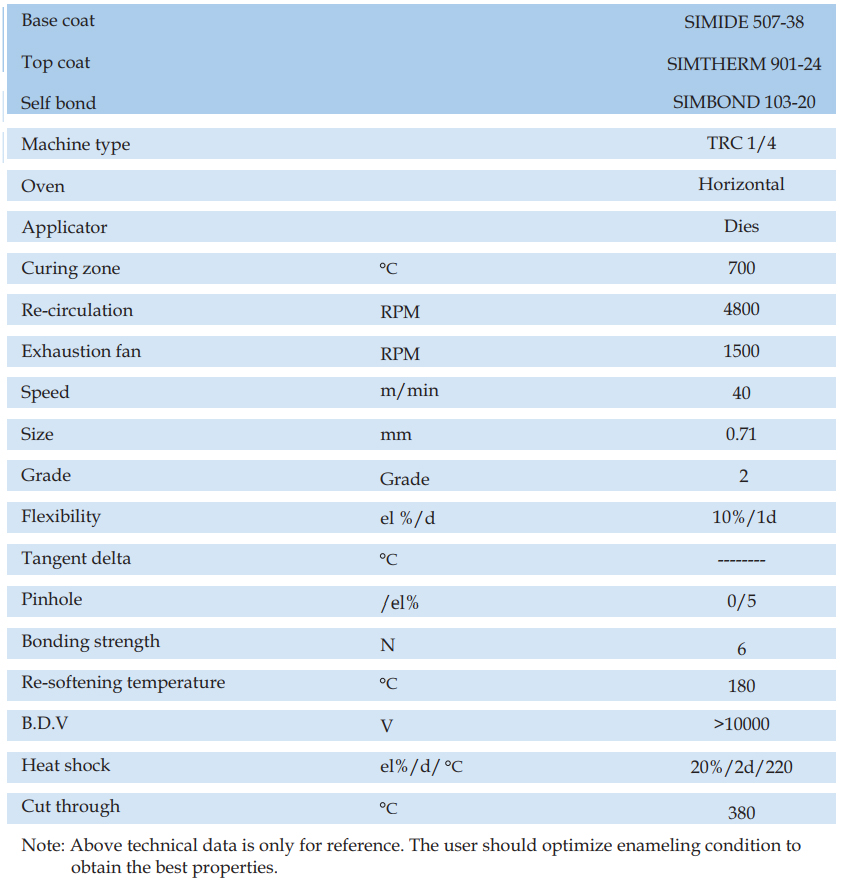

ENAMELED WIRE TEST RESULT

This is aromatic polyamide based enamel, as compared to aliphatic polyamide enamel. It has higher re-softening temperature and can work at high thermal resistance self bonding coil, such as power tool. It can be used as bonding layer for polyester on polyamide wire by single oven, but for better result dual oven is recommended. The bonding coating oven should be 100 C lower than the base coating oven. It can bond at 180 C - 220 C and re-softening temperature is around 170 C - 200 C.

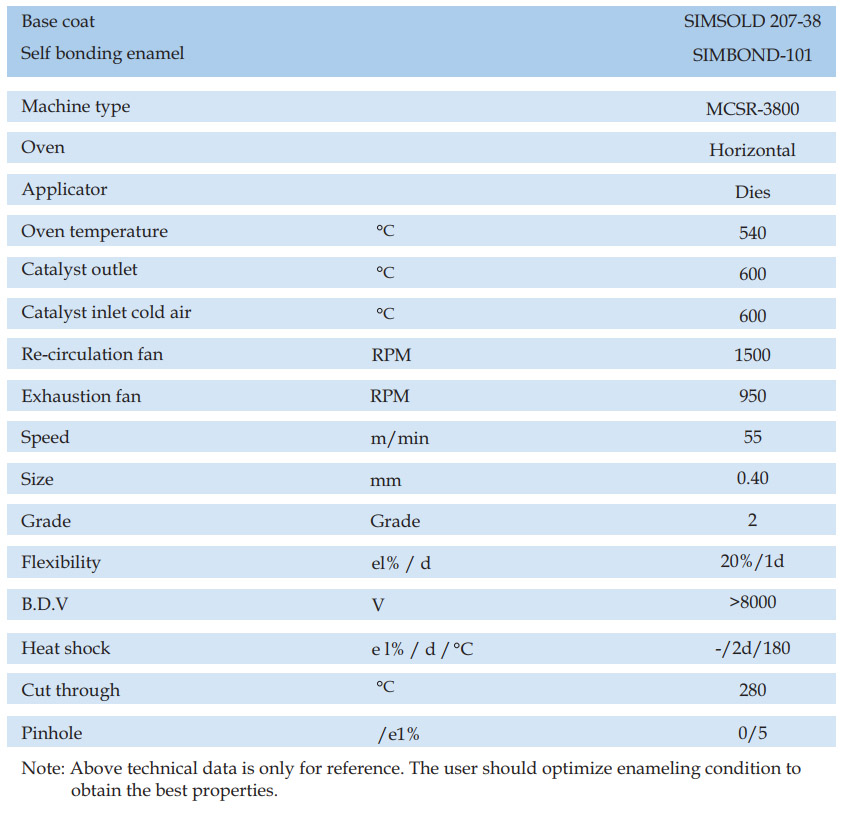

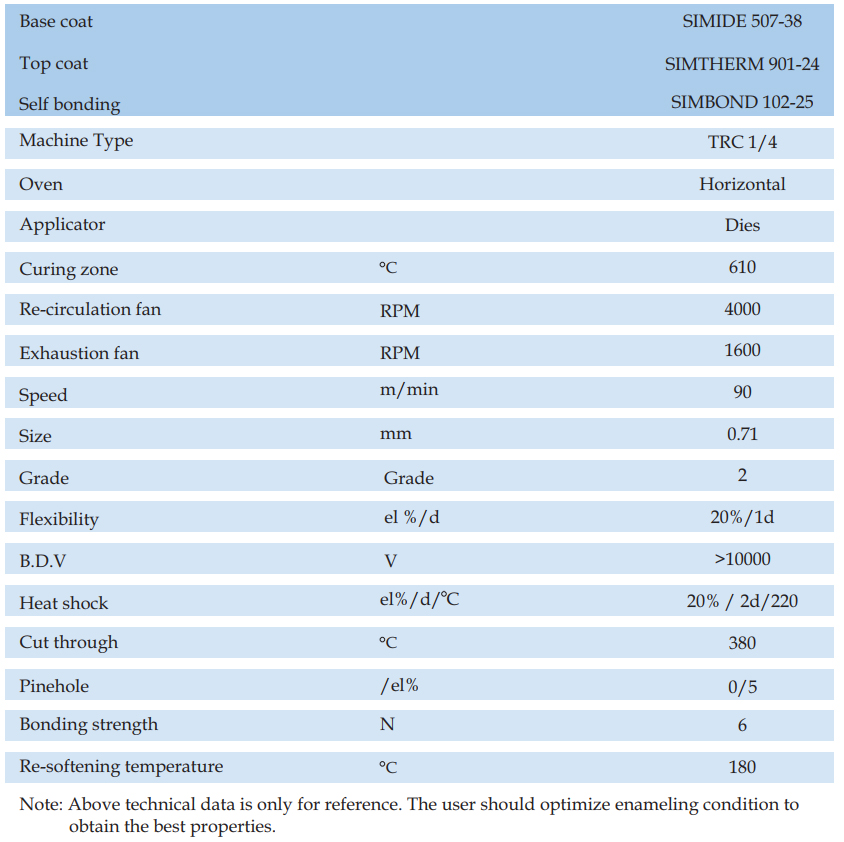

ENAMELED WIRE TEST RESULT

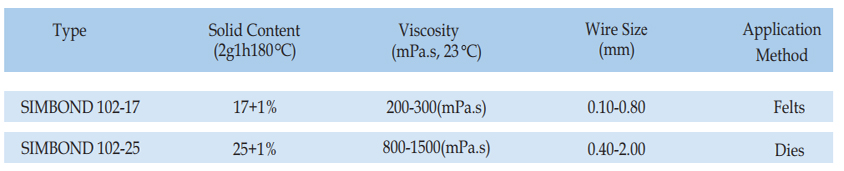

It is a self bonding enamel based on polyester. It is suitable to produce 180 & 200 class enamels. It is mostly used on high thermal resistance self bonding coil such as power tools. It can be used as bonding layer for polyester or polyesterimide enamel wire by single oven. It can bond at temperature 200 C - 240 C and re-softening good at 180 C.

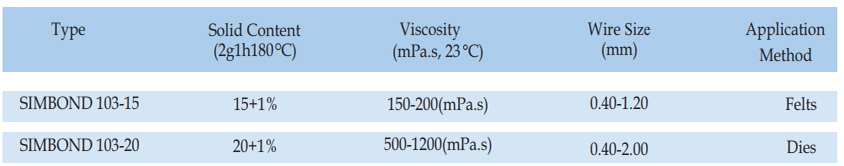

ENAMELED WIRE TEST RESULT